Plexiglass (acrylic) folding

From plane to spatial product: professional acrylic molding.

We provide professional organic glass (acrylic) folding services, turning flat sheets into three-dimensional, functional products. Using thermal forming technology, we precisely create a variety of angles and shapes.

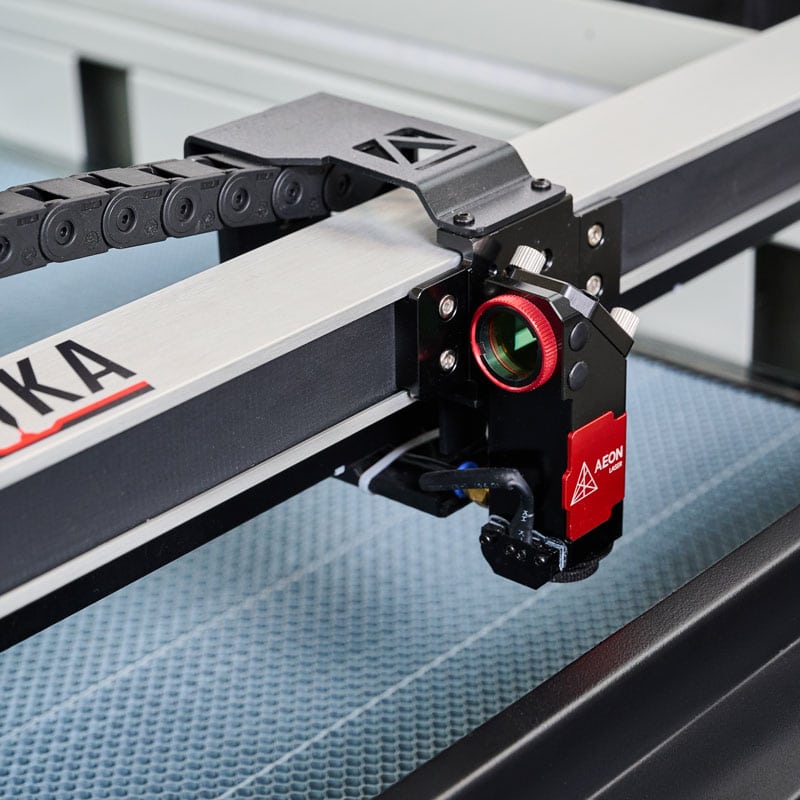

Acrylic folding is an integral part of production when creating stands, information brackets, protective covers or non-standard interior elements. This service is often combined with high-precision laser cutting, which allows you to extract a workpiece of any shape.

Spatial solutions made of acrylic for your business

Do you need a transparent, aesthetically pleasing and durable product for which a flat sheet is not enough? Glued seams are often visible, can be unsustainable and reduce the aesthetic value of the product.

Thermal bending of acrylic is a great alternative. Instead of gluing, we create a solid, molded mold that is not only more visually appealing, but also much stronger. This allows you to produce elegant, minimalist design products without any unnecessary connections.

Trading Equipment (POS/POP)

We produce various stands for products, brochure holders, price holders and information boards for points of sale. Transparent, curved acrylic emphasizes the product, does not distract attention and creates a professional image.

Protective covers and covers

We fold individually sized protective covers for exhibits, models, electronic devices or production equipment. The solid, curved construction provides maximum visibility and protection without weak glued seams.

Individual interior and office solutions

According to your drawings, we produce non-standard office accessories, shelves, document cases or decorative elements. By combining laser cutting and bending, we can implement a wide variety of design ideas.

Acrylic folding process: from idea to shape

Our manufacturing process ensures that each bend is done exactly to the drawing, and the final product is strong and aesthetically pleasing.

Discussion of the project

The process starts with your drawing. Using a laser, we cut out a precise flat shape of a part from an acrylic sheet of the desired thickness and color.

Project preparation

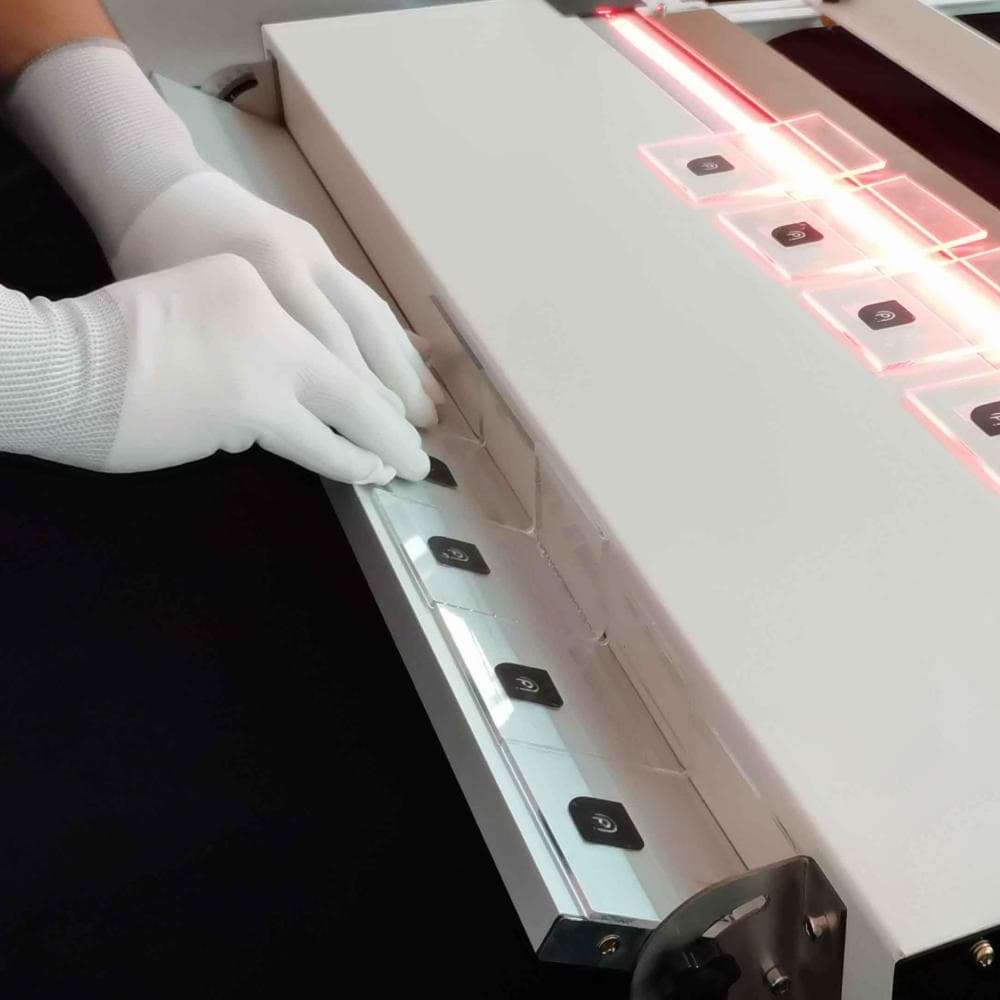

The cut workpiece is placed on a special folding machine. The narrow line, in which the bend is provided, is heated to a plastic temperature.

Project implementation

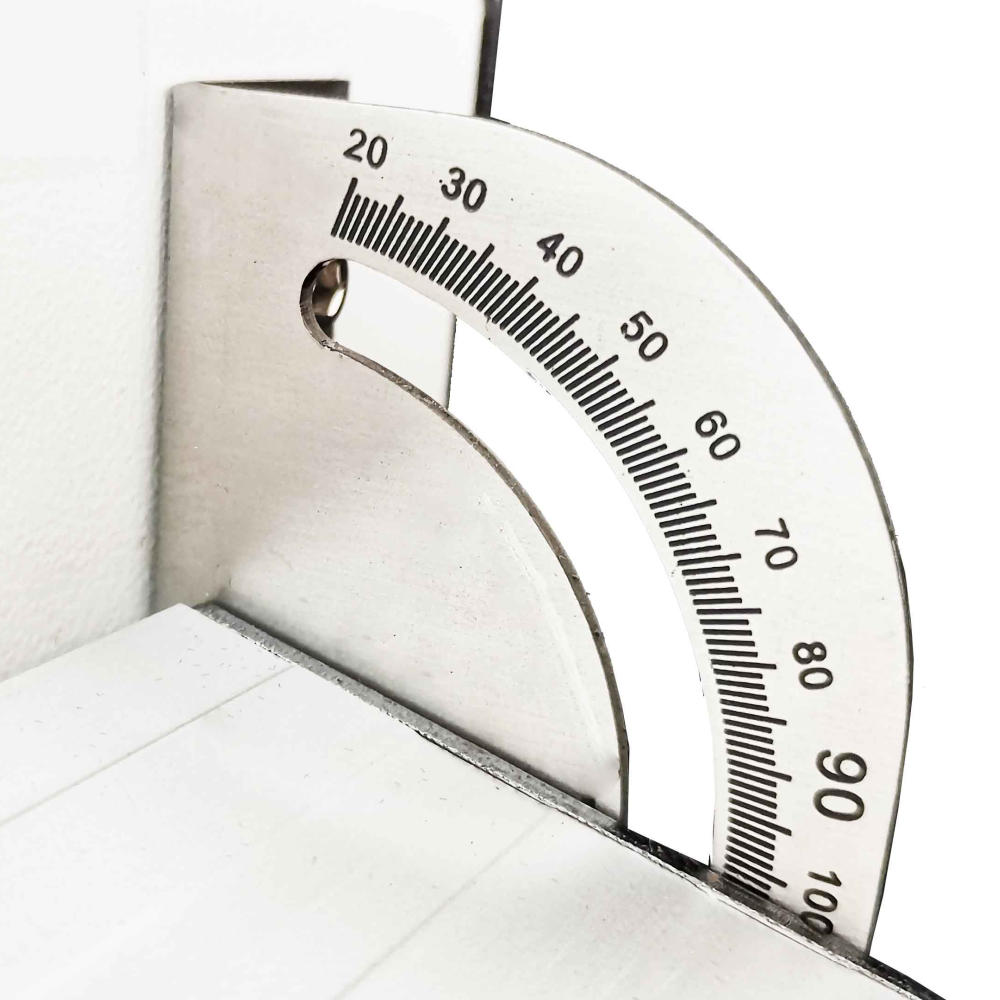

After reaching the required temperature, the acrylic is bent at the required angle using special templates. The part is kept until it cools down and locks into place.

Withdrawal

We check the quality, angles and dimensions of the final product. If necessary, we carry out additional processing. The product is prepared for collection or shipment.

Why choose us?

We are committed to quality, flexibility and reliability at every step.

Variety of technologies

All services – from cutting and engraving to printing and folding – are performed in one place. This saves you time and allows us to offer complex solutions by combining several production processes.

Accuracy and quality

We use high-end industrial equipment that ensures exceptional detail accuracy, high contrast and perfect repeatability, even for large product series.

Individual solutions

We work with both one-off prototypes and medium series. We are ready to delve into your needs and offer non-standard solutions tailored specifically to your project.

Help and advice

Not sure which technology is the most suitable? Our team will advise you, help you prepare the right files for production, and select the most optimal parameters so that the final result exceeds your expectations.

Turn a flat idea into a three-dimensional product!

Do you have an idea for a stand, hood or other three-dimensional product made of plexiglass? Contact us! We will consult, help you prepare the drawing and submit a proposal for the implementation of your project.

Contact UsCall Now