Laser Machine Repair and Service

Professional diagnostics, repair and maintenance of CO₂ lasers for the stability of your business.

We provide professional CO₂ laser machine service, which includes both urgent repairs and scheduled maintenance. We understand that every minute of downtime comes at a cost, so our goal is to quickly diagnose a fault and restore the upworking capacity of your equipment.

We provide warranty and post-warranty service, use high-quality spare parts and ensure the reliability of the work performed. Our experience allows us to effectively solve both mechanical, optical system or electronics problems.

Restore machine performance and avoid costly downtime

Unexpected machine stops, deteriorated cutting or engraving quality, unclear error messages on the control panel are all problems that disrupt production processes and cause losses. Trying to repair equipment on your own, without specific knowledge, often leads to even more serious breakdowns.

Professional laser machine service is an investment in stable work. We not only eliminate the consequences of the malfunction, but also determine the real cause of it, thereby preventing the recurrence of problems in the future.

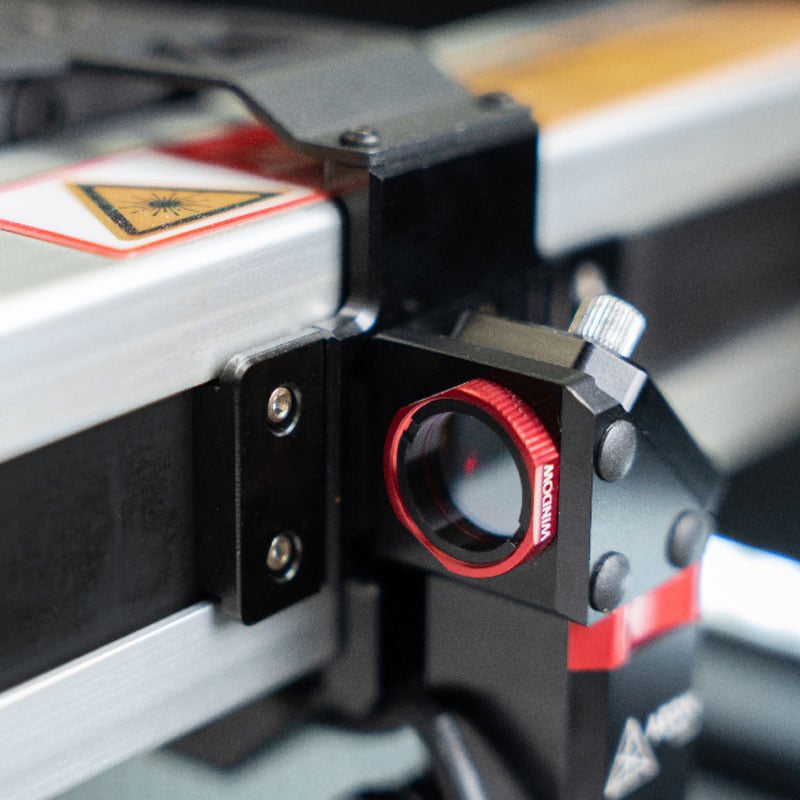

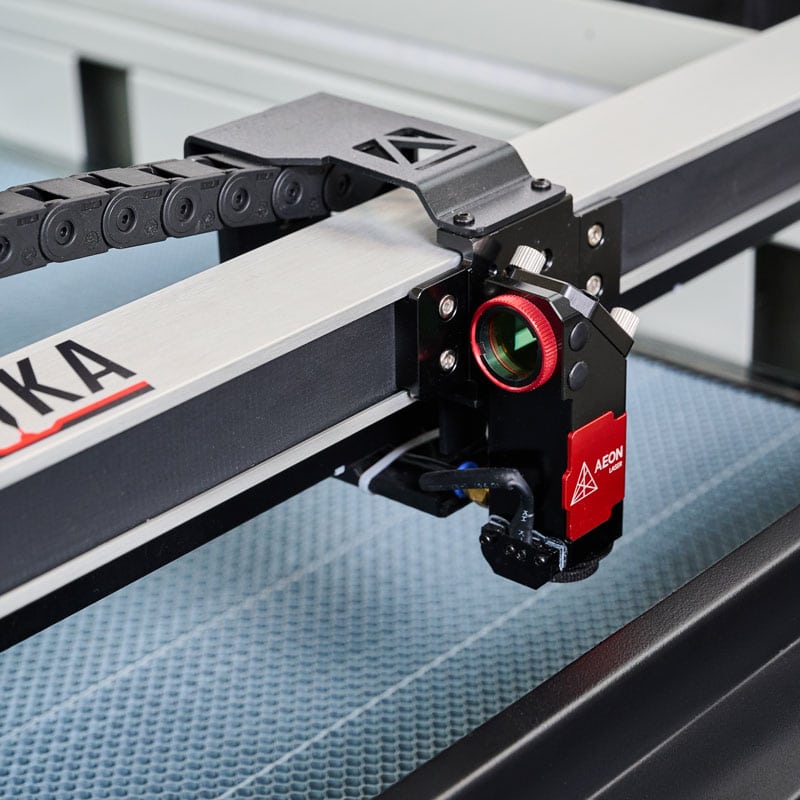

Optical System Maintenance and Calibration

Have you lost cutting power or have your engraving become blurry? The most common reason for this is misaligned or dirty optics. We perform professional cleaning, replacement of lenses and mirrors and precise calibration of the laser beam. This restores the accuracy and maximum power of the machine.

Repair and replacement of main units

We carry out all major repairs: from replacing faulty power supplies, controllers or motors to troubleshooting more complex mechanical failures. We specialize in laser tube (tube) replacement, ensuring safe installation and optimal performance of the new component.

Periodic maintenance

The best repair is the one that can be avoided. We offer a regular technical service that includes a full inspection of the machine: cleaning and lubrication of the mechanics, assessment of the condition of the optics, inspection of the cooling system and general diagnostics. This extends the life of the equipment and reduces the risk of unexpected failures.

Our service process: fast and transparent

Our goal is to get your equipment back on track as quickly as possible, with clear information about every step of the process.

1. Fault registration

Contact us by phone or email and describe the problem in as much detail as possible. During the initial consultation, we may ask you to send photos or videos to assess the situation more quickly.

2. Diagnostics and estimate

Our technician comes to you or performs remote diagnostics. Once the cause of the fault has been identified, we provide a transparent estimate of the work and the necessary parts. We start repair work only after receiving your approval.

3. Repair and testing

We professionally carry out all the necessary repair work, using quality spare parts. After the repair, the machine is thoroughly tested – we carry out test cuts and engraving to make sure that the equipment is working perfectly.

4. Referral and consultation

We hand over the repaired equipment to you, provide a report on the work done and answer all questions. We provide recommendations for follow-up care to avoid similar problems in the future.

Why choose us?

Our experience is a guarantee of the stability of your production.

Over 10 years of experience

Over more than a decade, we have accumulated invaluable experience. We don’t just sell equipment – we know it down to the smallest detail. This knowledge allows you to quickly and accurately diagnose faults and find the most effective solutions.

Practical knowledge

We have successfully installed hundreds of laser machines in a wide variety of businesses in Lithuania – from small workshops to large manufacturing companies. We have a strong understanding of the specific needs of our customers and potential challenges.

Spare parts in stock

We understand that downtime comes at a cost. That’s why we keep the most important spare parts locally. This allows you to minimize repair time and quickly restore the uptime of your equipment.

Reliable partners

Our goal is not only to repair, but also to help prevent breakdowns in the future. We share our experience, advise on equipment maintenance, optimization, and train on how to work more efficiently.

Your laser machine has stopped?

Do not wait for a minor malfunction to turn into a serious problem. Contact us now for professional advice. We will react quickly and help restore the stability of your production processes.

Contact UsCall Now