DTF printer for printing on clothes

DTF (Direct-to-Film) printers are an innovative textile printing technology that allows you to create colorful, bright and durable designs on T-shirts, sweatshirts, bags and other fabrics. It is a convenient solution for small businesses, advertising agencies or creative projects, because printing does not require complex preparation processes, and the result is obtained quickly and qualitatively.

Description

xTool Apparel Printer – One-Click DTF Printer

xTool Apparel Printer creates a DTF printing solution where the entire process – printing, powder coating, drying – takes place automatically with a single click.

???? ???????? One-Click Print-to-Bake Process

All steps – printing, powder coating, shaking, drying – are integrated into one system. Convenient work process without manual switching to different devices.

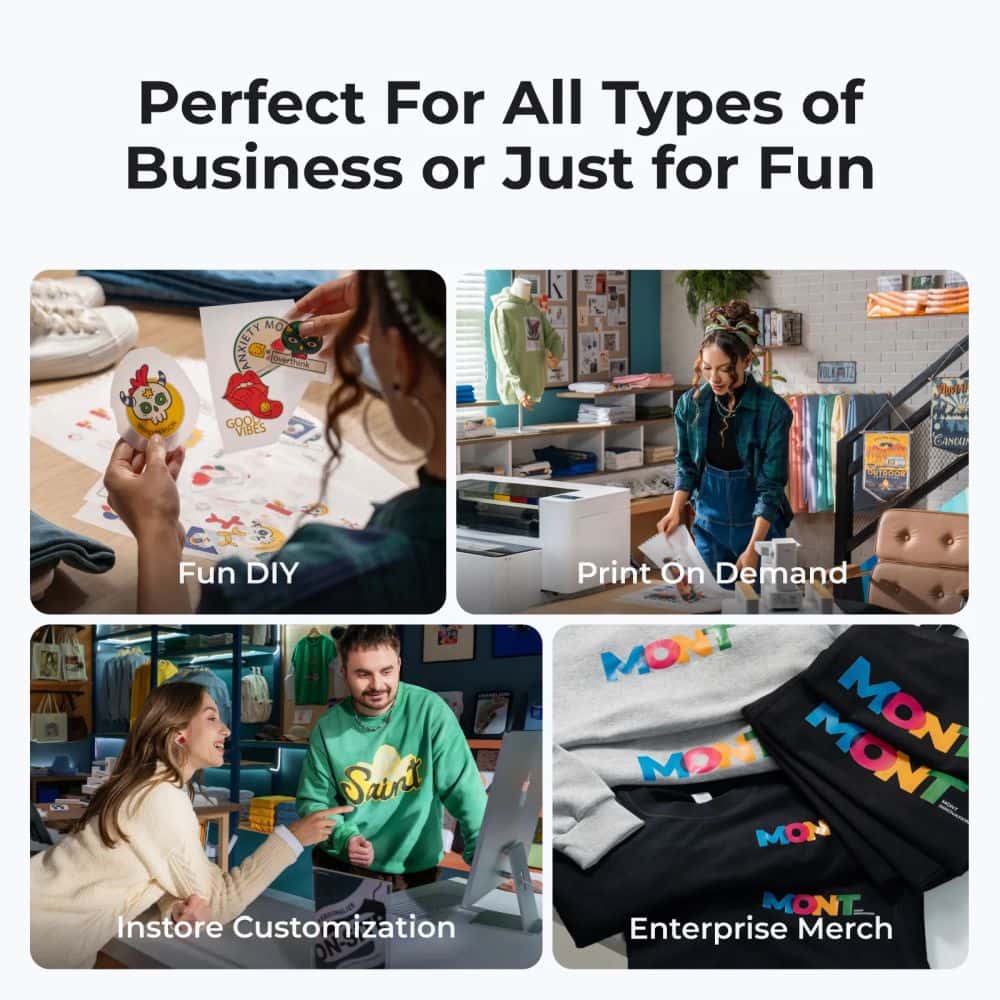

???? Prints on all fabrics

The device works with both light and dark fabrics without compromise. Can print on T-shirts, sweatshirts, bags and other types of fabrics.

???? Maintenance and automatic maintenance (SmartCycle™)

The printer continuously monitors humidity and temperature, automatically cleans print heads, and circulates white ink to prevent clogging.

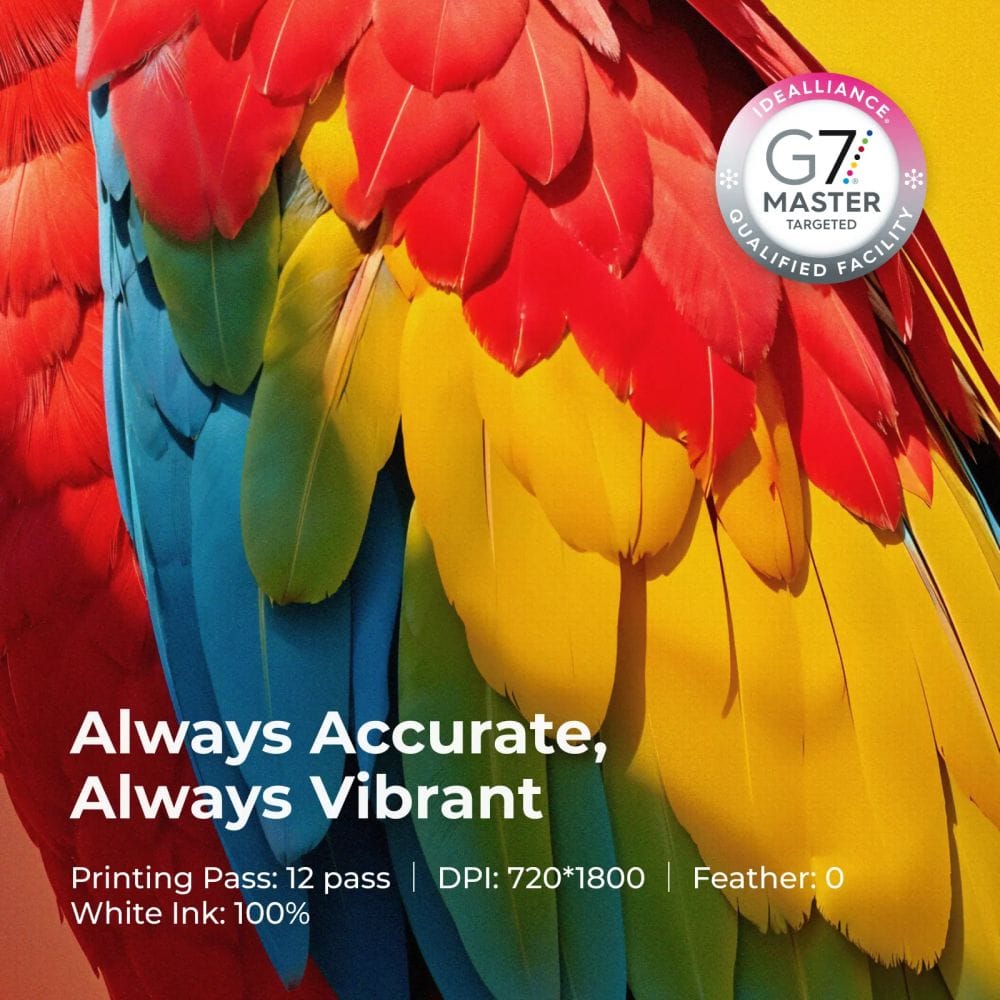

???? Color accuracy and technology

- Dual Epson I1600 printheads are used, which work together – one applies colour and the other white ink on dark fabric.

- G7 Certification – Colors are managed to accurately reproduce in accordance with industry standards.

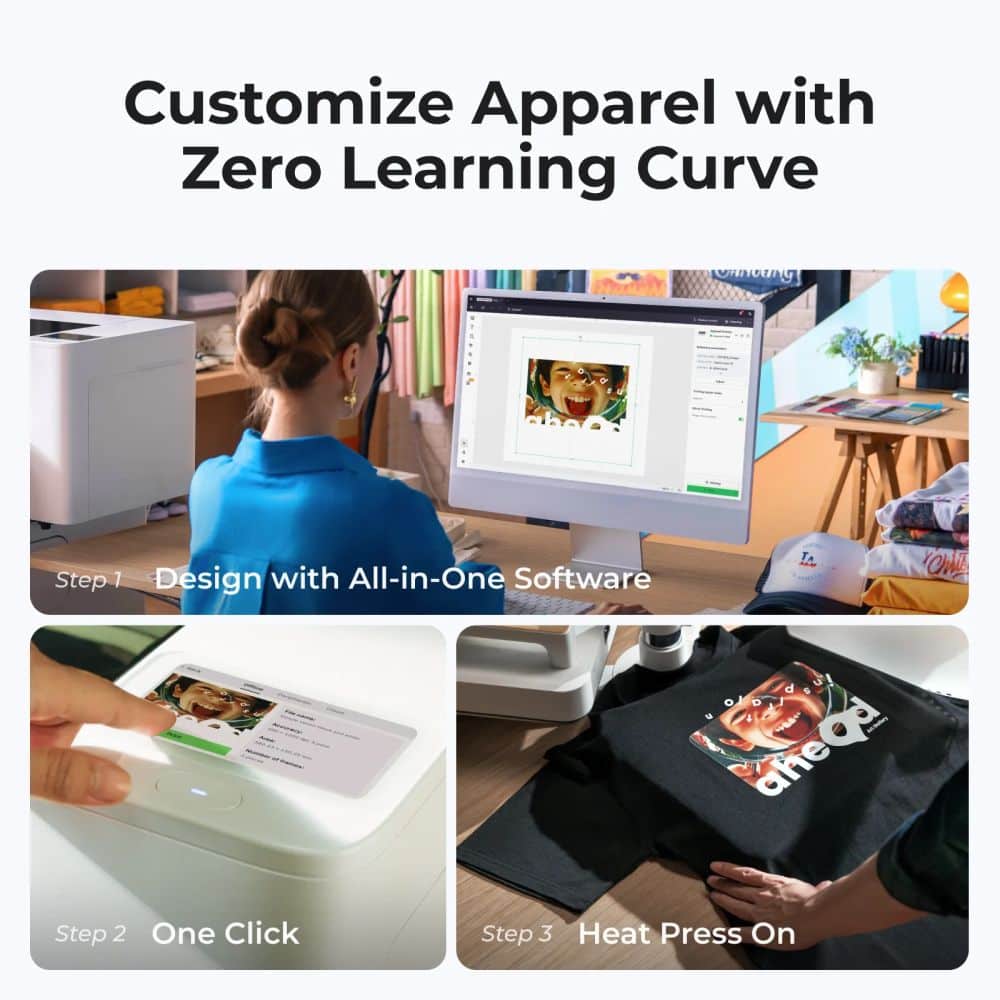

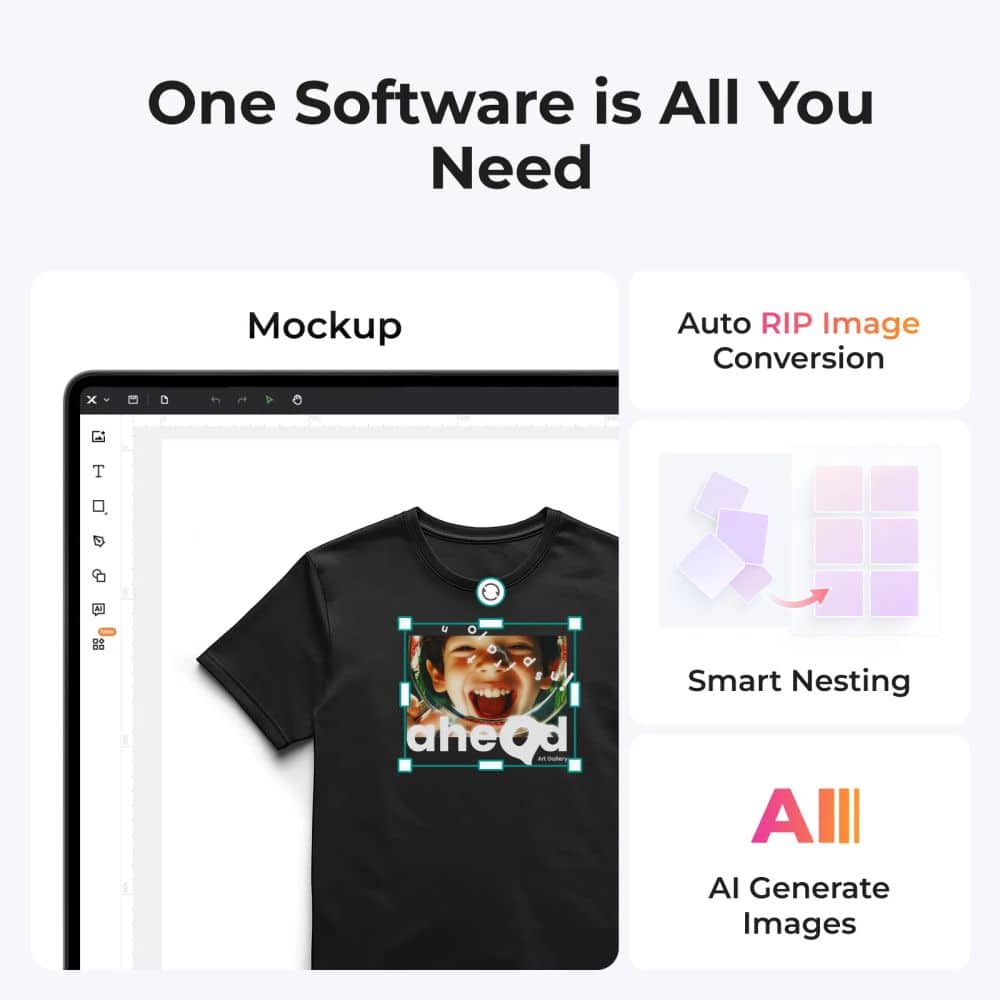

???? All-in-One Software, Print with Ease

The entire workflow – from design to ready-made film – is managed in a single software.

- No more connecting 3-5 separate apps or add-ons.

- An intuitive interface designed for both beginners and professionals.

- The ability to print accurately and consistently, without additional work.

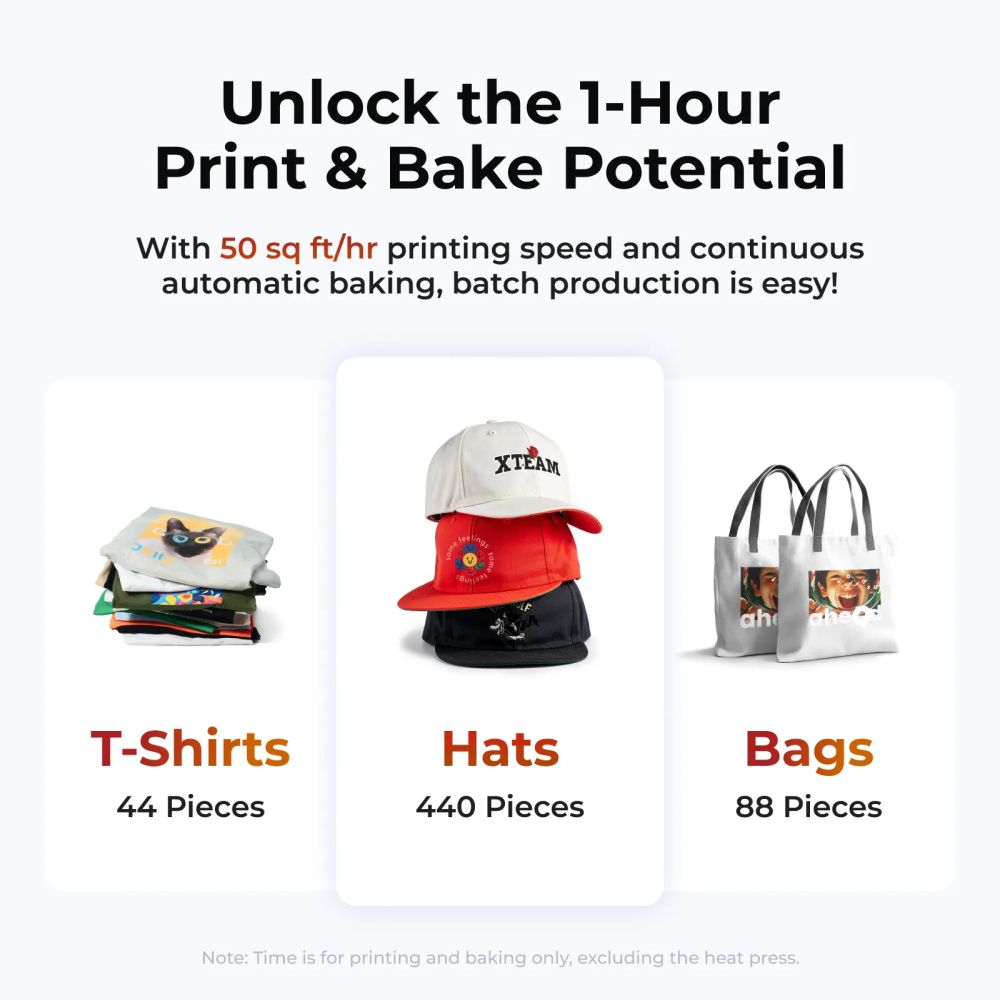

⏱️ Unlock the 1-Hour Print & Bake Potential

With Print-to-Bake automation, xTool Apparel Printer allows you to prepare about 4.6 m² of printed and baked film in 1 hour.

- Efficient in serial production.

- Suitable for both small and medium-sized batches.

- Allows you to reduce the need for labor and the number of errors.

⚙️ Operating parameters

| Setting | Value |

|---|---|

| Print Width | 356 mm |

| Maximum Print Area | 356 mm × 460 mm |

| Printing Mode | Single Sheet-Fed/Roll-Fed (will be introduced later) |

| Print heads | New Generation Dual Print Heads |

| Color management | G7 Color Standard |

| Compatible systems | Windows / macOS |

| Dimensions (Printer Solo Size) | 905 × 365 × 356.5 mm |

| Weight | 34 kg |

| Printer Sleep Mode Power Consumption | 23.5 W (approx. 0.5 kWh per day) |

| Operating Temperature | 15-30 °C (20-30 °C recommended) |

| Operating Humidity | 30% – 80% RH (recommended 50% – 80%) |

Available kits:

|  |  |

| Standalone | Versatile bundle | All-in-One bundle |

| Only the printer, without shaker-oven or filter equipment, is intended for those who already have drying and processing equipment. | Printer + automatic shaker-oven (powder coating, shaking, drying) — a quick start. | Complete package: printer + shaker-oven + air filtration unit — a professional, safe and ready for full production environment. |

Additional information

| Use cases | Printed from |

|---|