CO2 laser engraving machine

The CO2 Galvo laser engraving machine is a specialised tool designed for ultra-fast marking of organic materials. Using an innovative Galvo head with moving mirrors instead of the standard XY axis, this machine achieves speeds up to 10 times faster than plotter machines. The ideal solution for high-volume production where you need to mark wood, leather, paper, glass or plastic with serial numbers, logos or barcodes in a flash.

Description

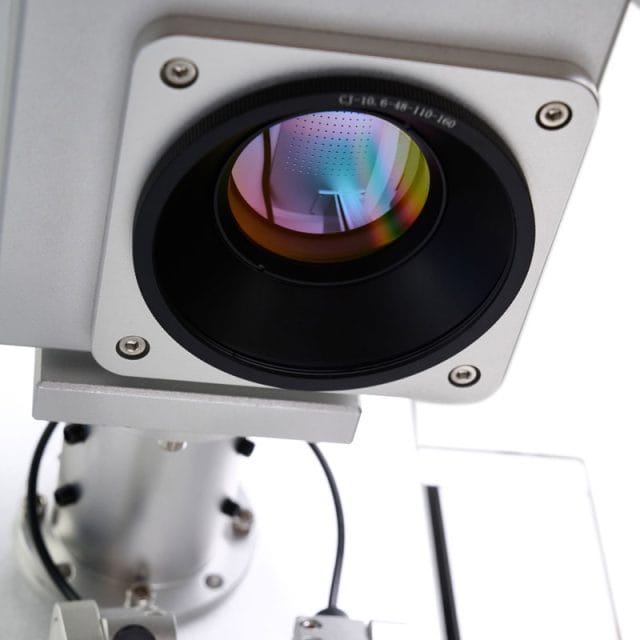

CO2 Head Laser: speeds no plotter can match

When it comes to mass production and speed of marking, CO2 Galvo laser machines are in a category of their own. Unlike traditional, plotter-type lasers that move mechanically along XY axes, the Galvo system uses two tiny, computer-controlled mirrors. These mirrors direct the laser beam to the correct point almost instantaneously, resulting in incredible marking speeds of up to 7000 mm/s. This is a specialised tool designed not for cutting, but for a single purpose: maximum speed and precision surface marking.

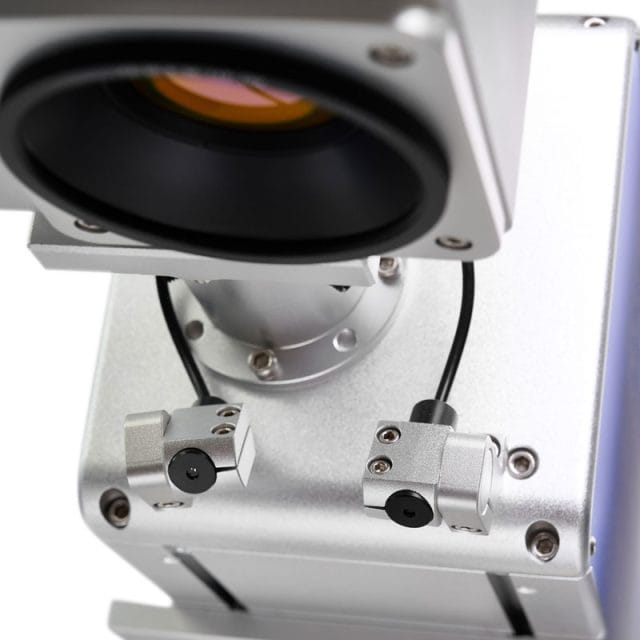

How does Galvo Technology work?

Instead of moving the heavy mechanical head over the entire working area, the Galvo system keeps the laser source and workpiece stationary. The laser beam is directed to two galvanometer motors that drive the mirrors. These mirrors can rotate thousands of times per second, so that the laser spot on the surface of the material moves at lightning speed. The result is up to 10 times more productivity compared to standard laser machines for the same engraving tasks.

The ideal tool for your production

Thanks to its speed and precision, the CO2 Galvo laser is indispensable in many applications. It is ideal for marking materials affected by the wavelength of the CO2 laser.

Preferred Materials:

- Wood and wood products: veneer, MDF, solid wood.

- Leather and textiles: Natural and synthetic leather, denim, felt.

- Paper and cardboard: marking of packages, engraving of invitations.

- Glass and ceramics: matt effect extraction, surface engraving.

- Most plastics: Acrylic (PMMA), ABS, polycarbonate.

- Painted metals: the laser can remove the paint layer, exposing the underlying metal.

Examples of use:

- Marking of serial numbers, expiry dates and barcodes on packaging.

- Engraving of logos and brands on wooden souvenirs or leather goods.

- Creating fine and intricate patterns on glass or ceramics.

- Quick personalisation of plastic enclosures or electronic components.

Long-term Investment: the RF Laser Source

These machines use a durable, air-cooled metal RF (radio frequency) laser tube. Unlike glass tubes, which need to be replaced periodically, RF sources have a service life of over 20 000 hours and can be refilled. This ensures minimal maintenance and stable laser power throughout the lifetime of the laser, making these machines a reliable long-term investment.

SPECIFICATION | |

| Laser Source | DAVI |

Laser Power | 30W, 40W, 45W, 50W, 60W |

| Pulse Range | 1 – 500kHz |

Engraving Speed | 0 – 7000mm/s |

| Minimum Line Thickness | >0.01mm |

Laser Wavelength | 10.6um |

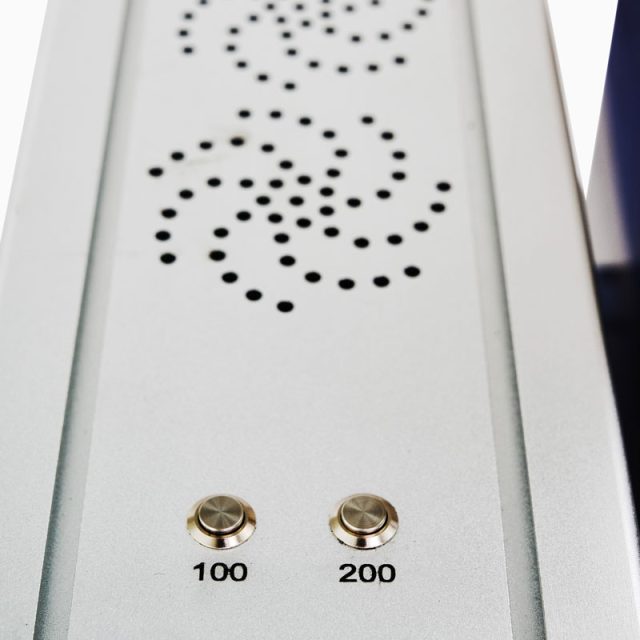

| Working Field | 100x100mm, 140x140mm, 150x150mm, 300x300mm |

Cooling | Air |

| Laser Source Lifetime | Up to 20 000 hours |

Power Supply Voltage | 230VAC, 50-60Hz |

| Energy Consumption | <= 500W |

Temperature / Humidity Level | 0~35°C / 10~95% |

| Machine Tool Dimensions and Weight | 660x240x500mm, 35kg |

Software | EzCAD (LightBurn Pro recommended, separate paid licence) |

| Supported File Formats | AI, PLT, DXF, BMP, DWG, DXP, PNG, JPG etc. |

Suitable Materials | Wood, plywood, leather, plastic, acrylic, rubber, glass, crystals, ceramics, paper, cardboard, ABS, jeans, clothing, polymers, etc. |

| Rotary | Additional Option (for rings, pens, Chuck, etc.) |

Additional information

| Material | |

|---|---|

| Use cases | marking |