Aeon Super Nova S Redline 10/14/16

AEON Super NOVA S REDLINE is the absolute pinnacle of laser technology, designed for uncompromising production. The unique hybrid system with two heads (standard and CO2 Galvo) allows cutting and ultra-fast marking in a single task. The integrated positioning camera, AC servo motors and Clean Pack technology make REDLINE the most powerful and versatile CO2 laser centre on the market.

Description

AEON Super NOVA S REDLINE: Hybrid Power Without Analogues

The AEON Super NOVA S REDLINE is the most advanced development by AEON engineers for industries where performance and flexibility are critical. This model takes the best of the Super NOVA series and takes it to a new level by integrating a revolutionary hybrid system with a CO2 Galvo scan head. The Super NOVA S REDLINE is designed to perform the most demanding combined tasks – cutting, engraving and ultra-fast marking – in a single process, saving a huge amount of time and opening up completely new production possibilities.

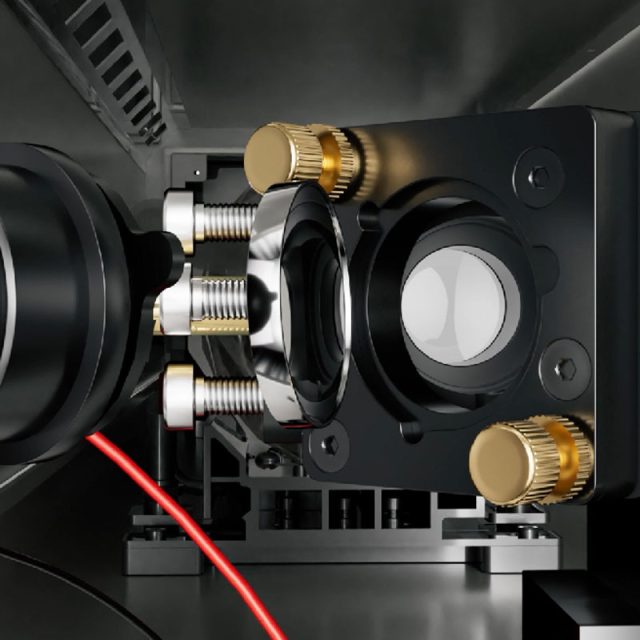

Revolutionary Hybrid Technology: two heads on one axle

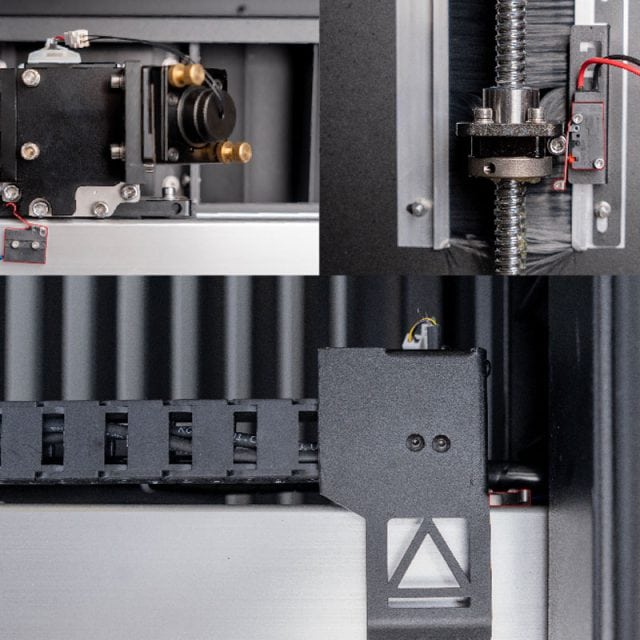

The Super NOVA S REDLINE is a unique system in which two completely different laser heads are mounted on the same moving axis. The software automatically switches between them depending on the operation being performed.

1. Standard Cutting and Engraving Head

This head, connected to a powerful glass CO2 laser tube (100-150W), is responsible for cutting and deep engraving tasks. It ensures precise and efficient cutting of thick materials such as wood, acrylic or veneer, just like the standard NOVA series machines.

2. CO2 Galvo Scanning Head

This is the true “superpower” of Super NOVA S REDLINE. This head, coupled to a durable metal RF laser tube, uses not a moving axis but ultra-fast mirrors to direct the laser beam. This enables absolutely incredible marking and engraving speeds, which are 30-50 times faster than standard XY-axis systems. It is ideal for marking serial numbers, barcodes, logos or any other fine graphics.

Single Process Production: cut and mark in one year

Imagine the process: a standard head cuts out the contour of the product and the Galvo head instantly maps it with the necessary information. All this is done in a single job, with no need to transfer the product to another machine. This not only dramatically increases productivity, but also ensures absolute precision by avoiding any positioning errors.

Top Class Package

As befits a flagship, Super NOVA S REDLINE comes with all the possible benefits as standard:

- Built-in Camera: for visual positioning and print recognition(Print & Cut).

- AC Servo Motors: for maximum speed, acceleration and precision.

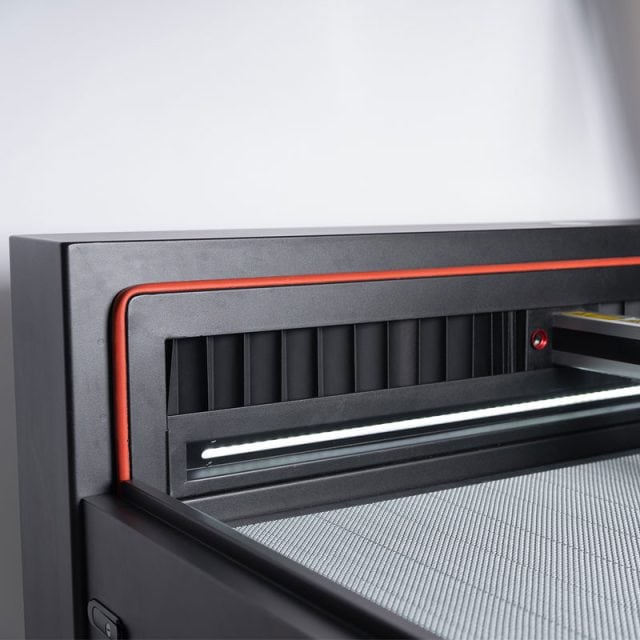

- “Clean Pack Technology: for protected and durable mechanics.

- Complete All-in-One Design: with integrated cooling, smoke cutoff and air supply.

- Motorised Table and Autofocus: for comfortable and fast work.

Choose your Super NOVA S REDLINE Production Platform

The Super NOVA S REDLINE series offers three sizes to adapt this cutting-edge technology to your production needs:

- Super NOVA S REDLINE10: 1000 x 700 mm working area.

- Super NOVA S REDLINE14: 1400 x 900 mm working area.

- Super NOVA S REDLINE16: 1600 x 1000 mm working area.

| SPECIFICATION | |||

| MODEL | NOVA10 SUPER Redline | NOVA14 SUPER Redline | NOVA16 SUPER Redline |

| Working area | 700×1000 mm | 900×1400 mm | 1000×1600 mm |

| Maximum motorised Z-axis height | 200 mm | 200 mm | 200 mm |

| Maximum lifting capacity | 120 kg | 120 kg | 120 kg |

| Laser type/power | DC Glass 90/100W | DC Glass 90/100/130W | DC Glass 90/100/130/150W |

| RF Metal 30/60W | RF Metal 30/60W | RF Metal 30/60W | |

| Maximum engraving speed | DC 1200 mm/s, RF 4000 mm/s | DC 1200 mm/s, RF 4200 mm/s | |

| Acceleration | 5G (DC) | ||

| 8G (RF) | |||

| Engine type | DC Stepper (DC) | ||

| AC Servo (RF) | |||

| Maximum resolution of DC source | 1000 DPI | ||

| RF source maximum resolution | 4000 DPI | ||

| Minimum size of letter engraving | 1 x 1mm (RF) | ||

| Positioning accuracy | < 0,01 mm | ||

| Cutting thickness | < 15mm (depending on material and source power) | ||

| Workbench | Cellular + special cutting work surface | ||

| Cooling | DC: Water cooler CW5000 | DC: Water cooler CW5200 | |

| RF: Air cooling | |||

| Smoke extraction fan | 500W | ||

| Intergrated air pump | 750W with 24L air capacity | 750W with 40L air capacity | |

| Autofocus | Built-in | ||

| Camera | 100° 8 megapixels | ||

| Safety classification of lasers | Class 1 laser product | ||

| Software | RDWorks (Lightburn recommended, separate paid licence) | ||

| Supported formats | DSP/PLT/BMP/DXF/AI/DWG/SVG | ||

| Machine dimensions | 1500*1210*1125 mm | 1900*1410*1125 mm | 2100*1510*1125 mm |

| Gross weight | 532 kg | 683 kg | 730 kg |

| Net weight | 415 kg | 560 kg | 566 kg |

| Power supply voltage | 220V AC 50Hz | ||

| Total power | 3300W | ||

| Rotary | Optional (Chuck/Roller) | ||

Additional information

| Use cases | cutting, engraving |

|---|